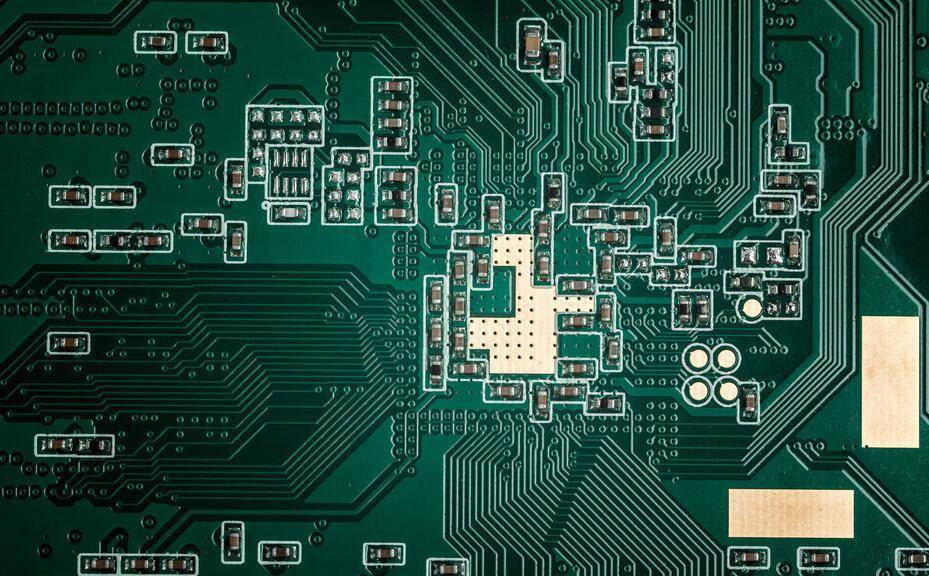

Three aspects that need to be considered when PCB board processing

The base material of PCB board can be divided into two types: organic materials and inorganic materials, each of which has its own unique advantages. Therefore, the determination of the substrate species considers various functions such as dielectric function, copper foil type, base groove thickness, and processability characteristics. Among them, the thickness of the surface copper foil is a key factor affecting the function of this printed circuit board. Generally speaking, the thinner the thickness is, the easier it is to etch and the fineness of the graphics have advantages.

2. Consider the setting of the production environment

The environment of the PCB board processing and manufacturing workshop is also a very important aspect. The regulation of ambient temperature and ambient humidity are both crucial factors. If the ambient temperature changes too significantly, it may cause the holes in the base plate to crack. If the environmental humidity is too high, nuclear energy will have an adverse effect on the function of the substrate with strong water absorption, which is specifically manifested in the dielectric function. Therefore, it is necessary to maintain proper environmental conditions when PCB boards are processed and produced.

3. Consider the selection of process flow

PCB manufacturing is easily affected by many factors, and the number of processing layers, punching process, surface coating treatment and other process processes will affect the quality of PCB board products. Therefore, for these process environments, PCB board processing and manufacturing are fully considered in combination with the characteristics of manufacturing equipment, and can be flexibly adjusted according to different PCB board varieties and processing requirements.